High nitrogen concentrations reduce the air quality in the Netherlands and nitrogen deposition acidifies the soil. This is especially a problem in nature areas. The construction sector is causing an increase in harmful concentrations. Therefore, low-nitrogen construction will almost certainly become the norm in the future.

This requires architects to design differently. Aspects such as construction methodology, use of materials, transport and energy consumption are balanced in a 'low-nitrogen design'. And good cooperation between the client, contractor, developer and architect becomes even more important.

low-nitrogen building

pi haaglanden care centre

With a pilot in Scheveningen, right next to two nature reserves, the Rijksvastgoedbedrijf (government property agency) and the DJI, du Prie bouw & ontwikkeling, cepezedprojects and cepezed show what is possible in the field of low-nitrogen construction. A new care centre is rising here within the walls of the PI Haaglanden. Although not required by law, it was decided to stay below a deposition of 0.005 mol N/ha/year when building the care centre. This target was guiding common choices from the outset. Each party takes a broad responsibility, with du Prie keeping control of logistics, amongst others. In a way, this real estate company acts as a launching customer.Construction started in June 2022 and the care centre will be completed in the summer of 2023. It is a temporary building that should serve for at least ten years.

construction methodology

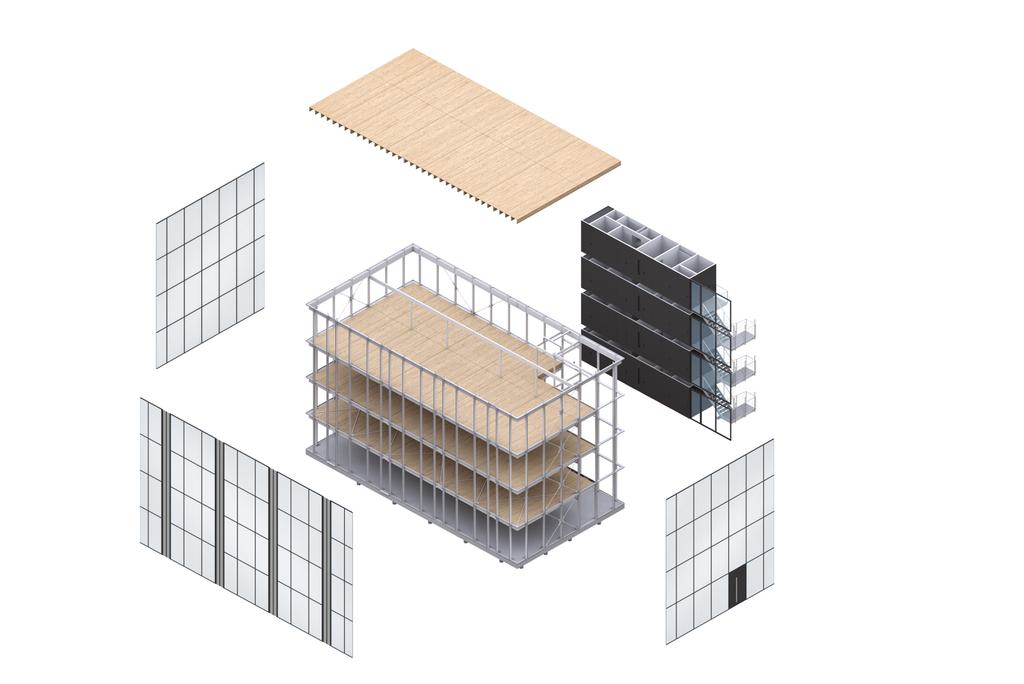

Low-nitrogen construction requires a fundamentally and radically different construction method. Partly with a view to reducing nitrogen emissions, cepezed designs buildings as a kit of parts. With prefab elements, the architect not only has more influence on the quality of the parts, but also more control over emissions. Polluting emissions are easier to capture and control in the factory than on the building site and the elements are assembled quickly and 'dry' on the building site. This shortens construction time and reduces the movements of individual personnel and suppliers to and from the building site.

all electric

Much can already be done with electric construction equipment. But if we want to fully commit to low-nitrogen construction, the quantity must increase: there is still too little electric construction equipment available. When designing, attention should be paid to the maximum weight of construction components so that they can be placed with light, electrically powered equipment. Opting for electric equipment not only reduces nitrogen emissions, it also means local residents (in this case the prisoners in the PI) experience less inconvenience from construction. For example, the foundation of the care centre was not driven with a diesel generator, but electrically screwed.

less material

By choosing high-quality and cleverly designed prefab elements, you can do with less material. Rough construction is all that is needed. Equipped with clever details, the prefab elements are multifunctional: in the PI, for example, the complete, concrete prefab units for the sanitary facilities in the wings simultaneously serve as partition walls and carry the roof. A building assembled with prefab components can be dismantled if it loses its function in order to be remounted elsewhere, in parts or as a whole. cepezed has been working in this way for 50 years and knows that it does not have to detract from the use value, atmosphere or experience.

transport

Not only traditional construction, but also traditional transport traffic pollutes. An important element of low-nitrogen construction is therefore optimising logistics. To keep transport movements to a minimum, each transport movement is organised as efficiently as possible. Prefab elements are supplied in flat packs wherever possible. Electric transport was the starting point; where this was not possible, Euro 6 trucks (the cleanest emission class) were chosen. du Prie set up a hub for the PI project to electrically transport construction personnel to and from the building site.

measuring is knowing

Nitrogen emissions were monitored on the construction site of the care centre. This made it possible to test the forecast - a detailed calculation was made prior to construction. Measurement can be done in many ways, in this case it involved tracking the running hours of fossil-fueled machinery and camera recording of license plates, to get an idea of the percentage of electric vehicles and different traffic classes (such as heavy traffic and stage 6 engines) in the total number of vehicles entering the construction site. The measurement data substantiate the experience of the parties involved in this pilot. These and other measurement results are needed to improve low-nitrogen construction in the future.

data

- the care centre is being built for use for ten years

- the care centre has a gross floor area of 3,300 m2

- during construction of the care centre, a nitrogen standard of <0.005 mol N/ha/year is targeted

partners: cepezedproject (project management), du Prie bouw & ontwikkeling bv (architectural execution), cepezedinterieur (interior), Buro Sant en Co (landscape architecture), LBP|SIGHT (advisor building physics, fire safety, nitrogen deposition), IMd Raadgevende Ingenieurs (construction), Overdevest (advisor installations), Van Eck Security Consultancy (safety matters), Timmers Praktische Bouwlogistiek (logistics on and around the construction site), Putman BV (implementation W-installations), Steegman Elektrotechniek BV (implementation E-installations)

general contractor: du Prie bouw & ontwikkeling

clients: Rijksvastgoedbedrijf en Dienst Justitiële Inrichtingen (DJI)

→ Want to know more? View the project page here

Would you like to discuss this further with us? → Mail bd@cepezed.nl or call our business development team at +31 (0)15 2150000

→ Mail bd@cepezed.nl or call our business development team on +31 (0)15 2150000